Designed, Manufactured and Tested

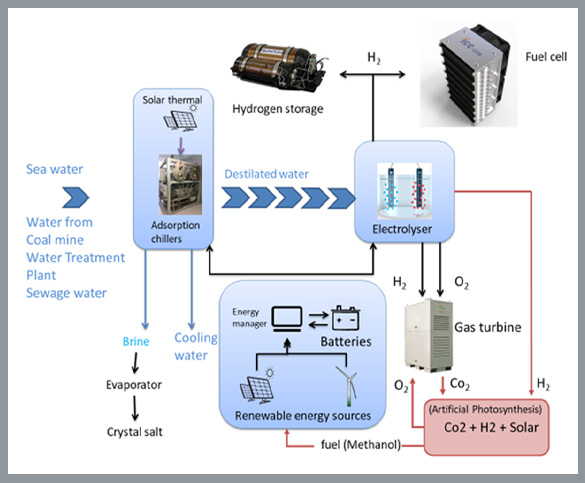

The technology of adsorption desalination of seawater and the production of high-purity distillate for hydrogen production will be developed in such a way that it can be scaled up at the implementation stage and obtaining a distillate production capacity of at least 40 kg / day in production hydrogen at least 1000 cm3 / min green hydrogen.

- To develop cutting-edge research in water desalination and energy production, with a specific focus on applications that lead to CO2 emission reductions.

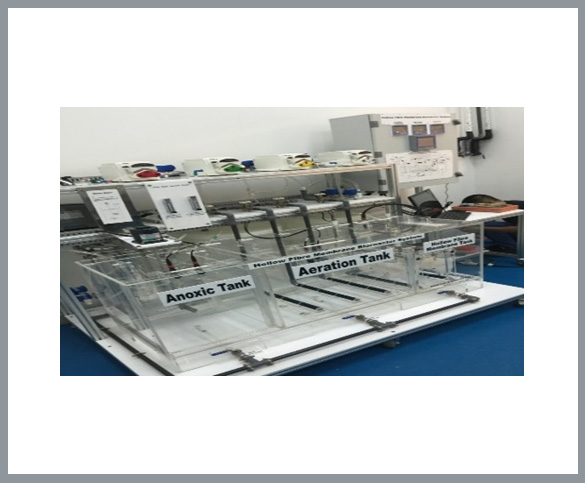

- The primary aim of this application is to reactivate of existing NETSAL Alfaisal Lab for Sorption Cooling and Desalination technology and establishment and operation of a state-of-the-art research lab and center focusing highly innovative seawater desalination technologies and its integration with hydrogen production.

- The technology of adsorption desalination of seawater and the production of high-purity distillate for hydrogen production will be developed in such a way that it can be scaled up at the implementation stage and obtaining a distillate production capacity of at least 40 kg / day in production hydrogen at least 1000 cm3 / min green hydrogen.

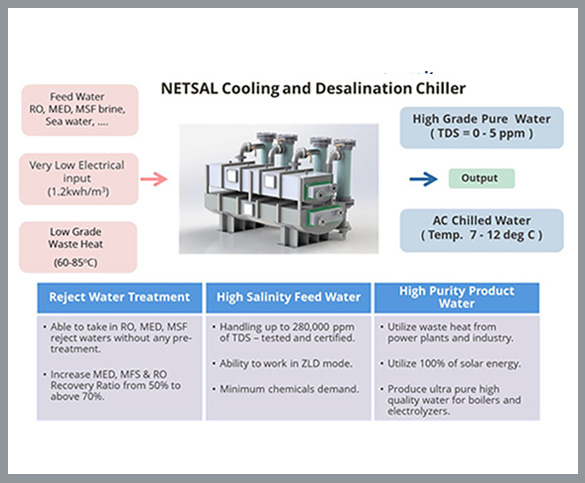

- The developed technology is a response to the growing demand for desalinated water and green hydrogen, resulting from the hydrogen and pro-ecological strategies adopted and implemented in the world. For the production of hydrogen, it is necessary to prepare pure process water used in electrolyzers and existing owned by Alfaisal adsorption desalination chiller NETSAL using fluidized adsorption beds producing distillate with lowest possible energy consumption will be a revolutionary solution on the global scale.

- The hydrogen produced can be used to produce electricity in fuel cells or burned in gas engines or gas turbines and can also be used to power hydrogen cars.

Alfaisal Lab has been already equipped with adsorption desalination chiller using fluidized adsorption beds produces in the most effective by energy and cost a very high purity distillate which will be used to produce hydrogen in the electrolyzer.

Benefits| Project Performance and Economical Target

To reduce the cost of green hydrogen production from the current level of 4 - 10 EUR per kg H2 towards 2 euro per kg H2 in 2050.

To develop offshore hydrogen production by means of water electrolysis installations.

To decrease transport costs and avoid large investments in electrical grids, since transporting gases is less expensive than transporting electricity additionally already existing gas infrastructure can be used.

The electrolysis process requires ultrapure water, which is an expensive feedstock in the KSA.